From Motorola to Microsoft - the world's best don’t just work hard, they work smart. And Six Sigma is how they do it.

What Is Six Sigma?

Six Sigma is a rigorous, data-driven methodology focused on reducing defects, improving processes, and achieving near-perfect quality in any system, manufacturing, service, tech, or finance.

The goal? Only 3.4 defects per million opportunities. Yes, it’s that precise.

But beyond stats, Six Sigma is a mindset- a structured way to solve problems, eliminate waste, and consistently deliver better results.

Why Organizations Embrace Six Sigma

Here’s why some of the world’s top companies invest millions in Six Sigma:

Enhance Product and Service Quality

It helps teams identify root causes of errors, not just symptoms, ensuring that problems don’t keep coming back.

Reduce Costs and Waste

By streamlining processes, Six Sigma eliminates rework, delays, and unnecessary complexity, directly improving the bottom line.

Boost Customer Satisfaction

When quality goes up and variability goes down, customers notice. Trust, loyalty, and satisfaction rise naturally.

Improve Efficiency and Productivity

Six Sigma is all about making things flow better. That means less downtime, fewer mistakes, and more focused effort.

Strengthen Competitive Advantage

In a crowded market, consistency is king. Companies that master process quality often outperform their peers long term.

How Major Companies Have Used Six Sigma to Their Advantage

Motorola, the birthplace of Six Sigma, adopted the approach to reduce manufacturing defects. Their success not only saved billions but also created a global benchmark in quality and efficiency.

General Electric (GE), under the leadership of Jack Welch, integrated Six Sigma into its company culture. This led to over $10 billion in savings within five years, transforming GE into a model of operational excellence.

Amazon leveraged Six Sigma to manage and scale its massive logistics network. The result? Faster deliveries, fewer order errors, and a supply chain that's become one of the most efficient in the world.

Ford Motor Company applied Six Sigma to address high defect rates and warranty claims. This reduced production costs, improved vehicle quality, and rebuilt trust in its brand.

Bank of America utilized Six Sigma to optimize both back-office processes and customer service, resulting in faster turnaround times, improved compliance, and increased customer retention in a highly competitive sector.

3M, a global innovation leader, integrated Six Sigma into over 30,000 projects to maintain product quality while continuing to innovate at scale.

Wipro improved its customer service by adopting Six Sigma techniques to identify and resolve recurring service issues, significantly enhancing client satisfaction.

Boeing turned to Six Sigma to improve safety and quality in its aerospace production lines, leading to reduced manufacturing errors and higher reliability.

Microsoft improved internal service operations and customer support systems using Six Sigma, resulting in higher satisfaction scores and streamlined workflows.

McKinsey & Company, a global consulting powerhouse, adopted Six Sigma to standardize project delivery and knowledge-sharing processes across teams, boosting efficiency and client satisfaction.

The Certification Path: From Beginner to Expert

Six Sigma certifications are divided into levels, each representing a deeper understanding of the methodology.

- White Belt is for absolute beginners who want a quick intro to Six Sigma concepts.

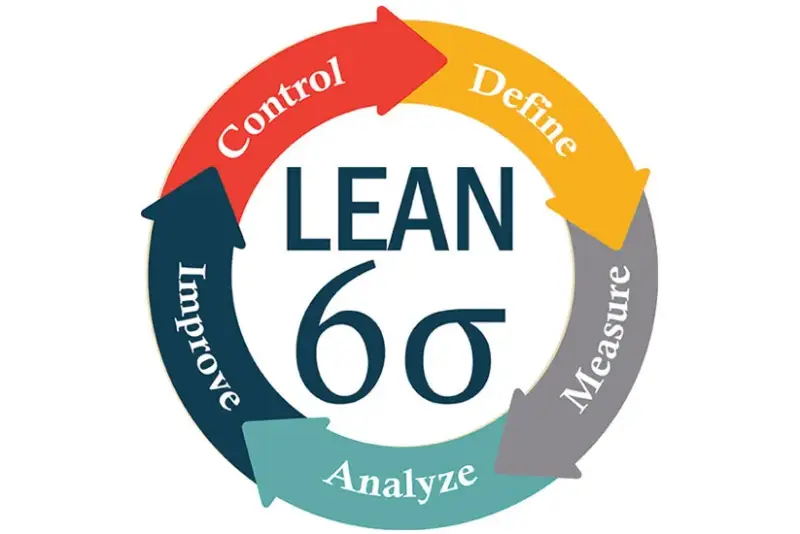

- Yellow Belt is ideal for students or freshers looking to understand the basic tools and techniques like DMAIC (Define, Measure, Analyze, Improve, Control).

- Green Belt is more advanced, professionals learn how to manage real Six Sigma projects and analyze data.

- Black Belt holders lead major transformation initiatives, often managing teams and strategic changes.

- Master Black Belt professionals train others, develop advanced strategies, and align Six Sigma with business goals.

If you're a student or just starting your career, Yellow or Green Belt is a great place to begin.

How to Get Certified

You don’t need to join a corporate training program to start learning Six Sigma. Plenty of online platforms offer accessible and affordable certification courses:

- Coursera – Offers university-backed programs

- Udemy – Budget-friendly and beginner-friendly

- LinkedIn Learning – Good for professionals

- GoLeanSixSigma – Practical, hands-on courses

- ASQ (American Society for Quality) – The most recognized certifying body for advanced levels

Start with a basic course and apply what you learn to a mini-project, maybe even something in your college, internship, or startup!

Is Six Sigma Right for You?

If you enjoy solving problems, making things work better, and leading through process thinking, Six Sigma could be a game-changer for you.

It’s especially useful if you’re in:

- Engineering (mechanical, industrial, computer science)

- Business or management

- Product development or operations

- Consulting, quality control, or data analysis

Conclusion: Lead with Clarity and Consistency

Six Sigma is more than just a technical certification, it’s a powerful approach to thinking critically, solving deeply rooted problems, and building systems that work.

The world doesn't just need people who hustle but it needs people who optimize, analyze, and improve. Whether you’re launching a startup, managing a project, or just starting your career, Six Sigma gives you a framework to drive real, measurable impact.

Discussion

Start the conversation

No comments yet

Be the first to share your thoughts on this article. Your insights could spark an interesting discussion!