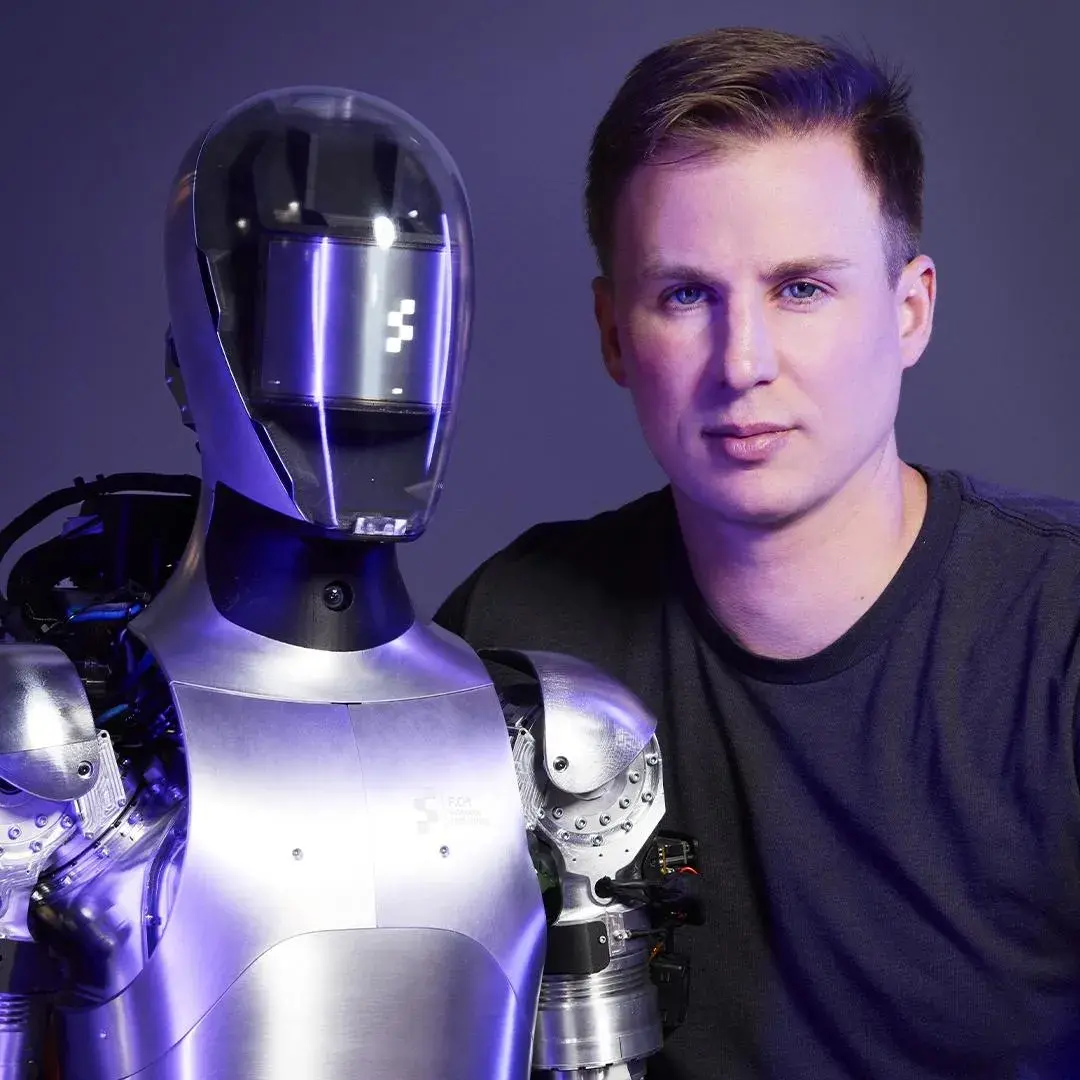

Imagine a co-worker who never gets tired of night shifts, learns new tasks overnight, and fits right into spaces built for people with hands that grasp, eyes that understand, and a voice that talks back.

That’s the promise behind Figure’s humanoid: a general-purpose robot designed to step into the real world’s messy, human-made environments and help. It’s not sci‑fi vapor; pilots are underway, big checks are being written, and the technology is advancing fast, sometimes faster than expectations, sometimes slower than the hype. But the direction of travel is unmistakable.

What makes this humanoid different

- Built for our world: Figure’s second-generation platform, Figure 02, is a 5'6" electric humanoid with upgraded hands, six onboard cameras, and 3x more onboard AI compute than its predecessor, letting it perceive, reason, and act without a safety cage in many scenarios.

- Talk, see, decide: Through a partnership with OpenAI, Figure 02 can hold speech-to-speech conversations, follow instructions, and apply a vision-language model for common-sense visual reasoning in real time crucial for fluid work alongside people

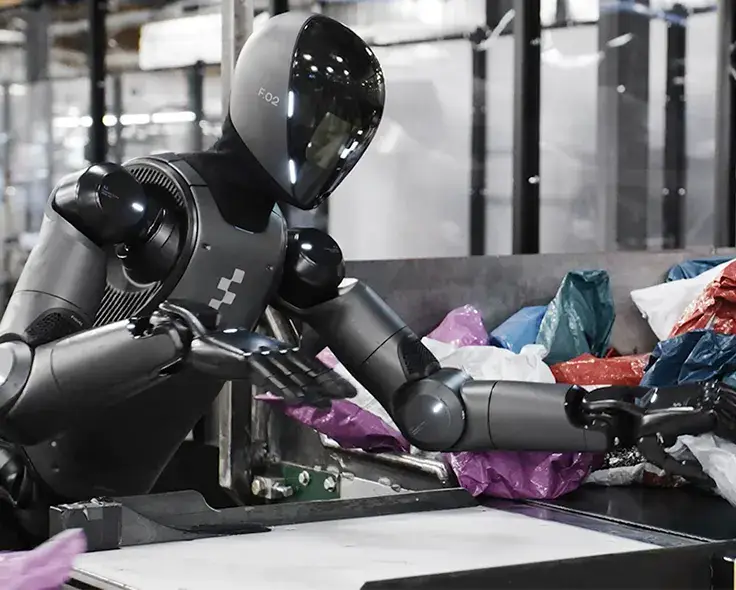

- Iterating in the real world: BMW has been testing Figure’s robot in Spartanburg, South Carolina, focusing on milestone-based, tightly scoped tasks like picking sheet-metal parts and placing them for downstream welding so the tech earns trust one job at a time.

The impact, near and far

- Factory floors first: The fastest wins are in logistics cells and repetitive, injury-prone tasks material handling, kitting, and line‑side support, where a humanlike form factor avoids expensive retooling and can be re-tasked with a software update.

- Safety by design: Natural language interaction plus perception-heavy autonomy helps the robot explain itself and follow instructions, while conservative motion and tactile control improve collaboration around humans.

- Measured reality: Despite bold ambitions, BMW’s rollout remains modest and controlled, with limited tasks during production hours exactly how safety-critical factories integrate new tech, and a reminder to separate promise from progress.

The money behind the momentum

- Big checks, bigger expectations: Figure raised $675M in early 2024 at a $2.6B valuation, backed by Microsoft, NVIDIA, OpenAI, Intel, and Jeff Bezos, setting the stage for aggressive R&D and first deployments.

- The step-up round: By February-March 2025, reports indicated talks to raise about $1.5B at a approx $39.5B valuation, a 15x leap that signals investor conviction in humanoids, even as the path to scaled revenue remains execution-heavy.

- Ambition at scale: Coverage has highlighted targets like 100,000 units by 2029 and multi-billion revenue aspirations, reflecting a market that sees general-purpose robots as a lever on labor shortages and productivity though timelines will hinge on reliability, uptime, and unit economics.

Inside the machine: Why Figure 02 matters

- Hands that matter: Fourth‑generation human-scale hands with 16 degrees of freedom and human-equivalent strength aim at the hardest problem in robotics, general manipulation, so the same robot can pack, kit, or sort without custom grippers.

- Sensing and compute: Six RGB cameras, upgraded batteries, integrated cabling, and stacked GPU modules enable faster inference and longer runtime, critical for shifting from staged demos to sustained, autonomous work blocks.

- AI as the gearbox: Onboard models compress perception, planning, and dialogue into fluid behavior, reducing the need for hand-coded routines and speeding up “learn a new task, redeploy” cycles across sites.

How this could reshape work

- From repetition to orchestration: As robots take on dull, dirty, dangerous tasks, human roles tilt toward oversight, exception-handling, and continuous improvement, with training shifting from tool use to systems thinking.

- Flexible automation economics: A general-purpose humanoid that can flip tasks by software update promises better utilization than fixed automation especially on off‑shifts and in brownfield facilities built for people.

- The consumer horizon: Reports suggest Figure sees a path to home use within years, but consumer-grade trust hinges on cost, reliability, and obvious everyday utility; today’s progress in factories is the proving ground for tomorrow’s kitchens and living rooms.

Hype vs. hard yards

- The signal: Speech-enabled, vision-grounded autonomy working alongside people and measured factory pilots that are expanding capability while controlling risk.

- The noise: Viral clips and lofty unit targets can overshadow the incremental grind; BMW’s pace shows how adoption really happens in safety-critical environments slow, steady, and evidence-led.

- The tell: Investor appetite hasn’t cooled; the reported $1.5B round at approx $39.5B valuation reflects a bet that embodied AI will be one of this decade’s defining platform shifts.

What to watch next

- Real KPIs: Cycle time, hours of autonomous operation per shift, uptime, and cost per task vs. human labor in live deployments.

- Learning efficiency: Fewer demonstrations to mastery and faster generalization across tasks, tools, and layouts.

- Deployment breadth: From one task in one cell to multi-cell, multi-shift operation then multi-site rollouts with stable maintenance and service loops.

Thoughts

Humanoids are moving from cinematic novelty to industrial necessity, and Figure’s robot sits at the center of that shift: humanlike where it counts, AI-first where it matters, and financed to run the marathon, not just the sprint.

The near term is about disciplined factory wins; the long term could be nothing less than a new kind of teammate that speaks our language, uses our tools, and scales our capacity, quietly rewiring what work looks like, one shift at a time.

Discussion

Start the conversation

No comments yet

Be the first to share your thoughts on this article. Your insights could spark an interesting discussion!